Profile Extrusion Aluminium Warshadaha

Profile Extrusion Aluminium Warshadaha

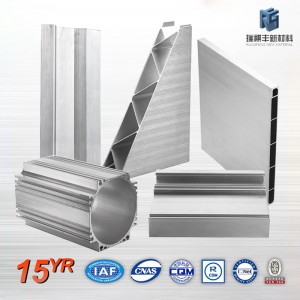

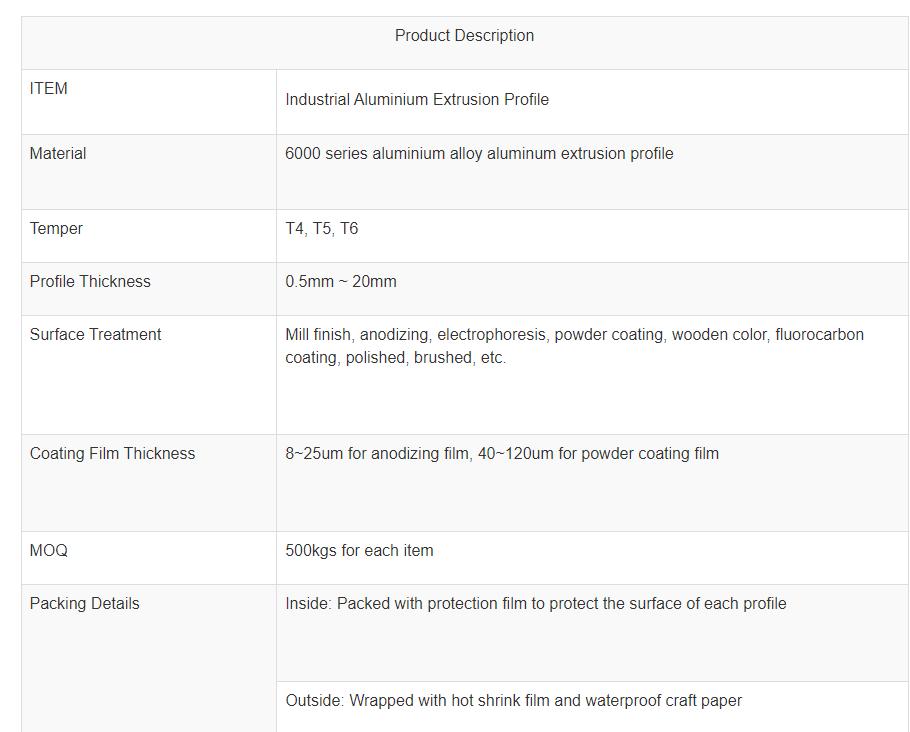

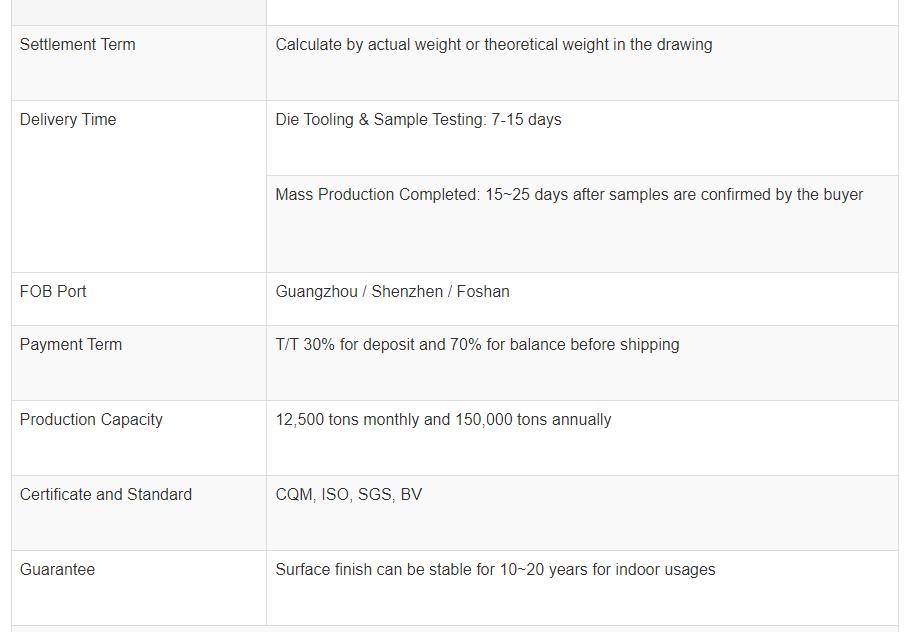

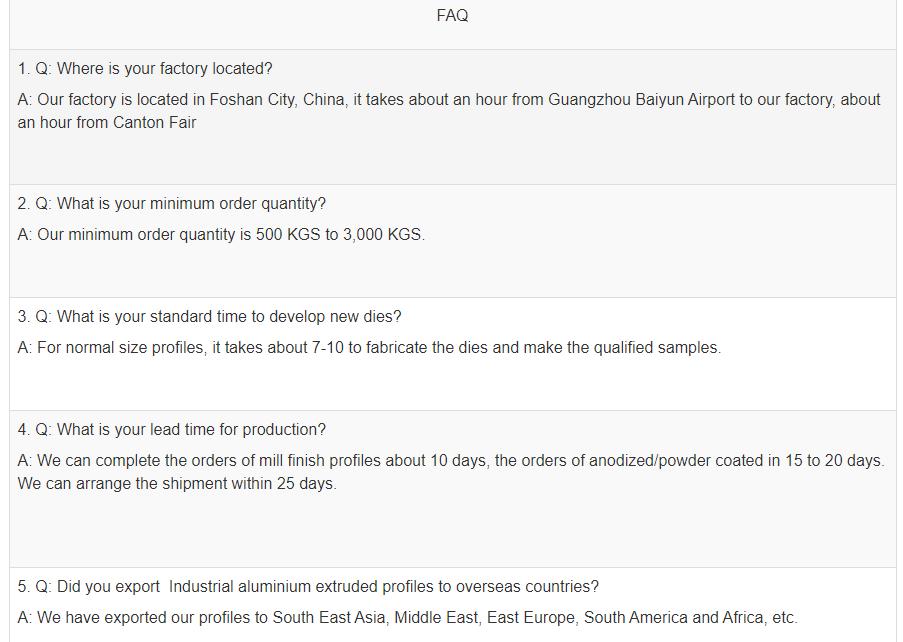

Sharaxaada Alaabta

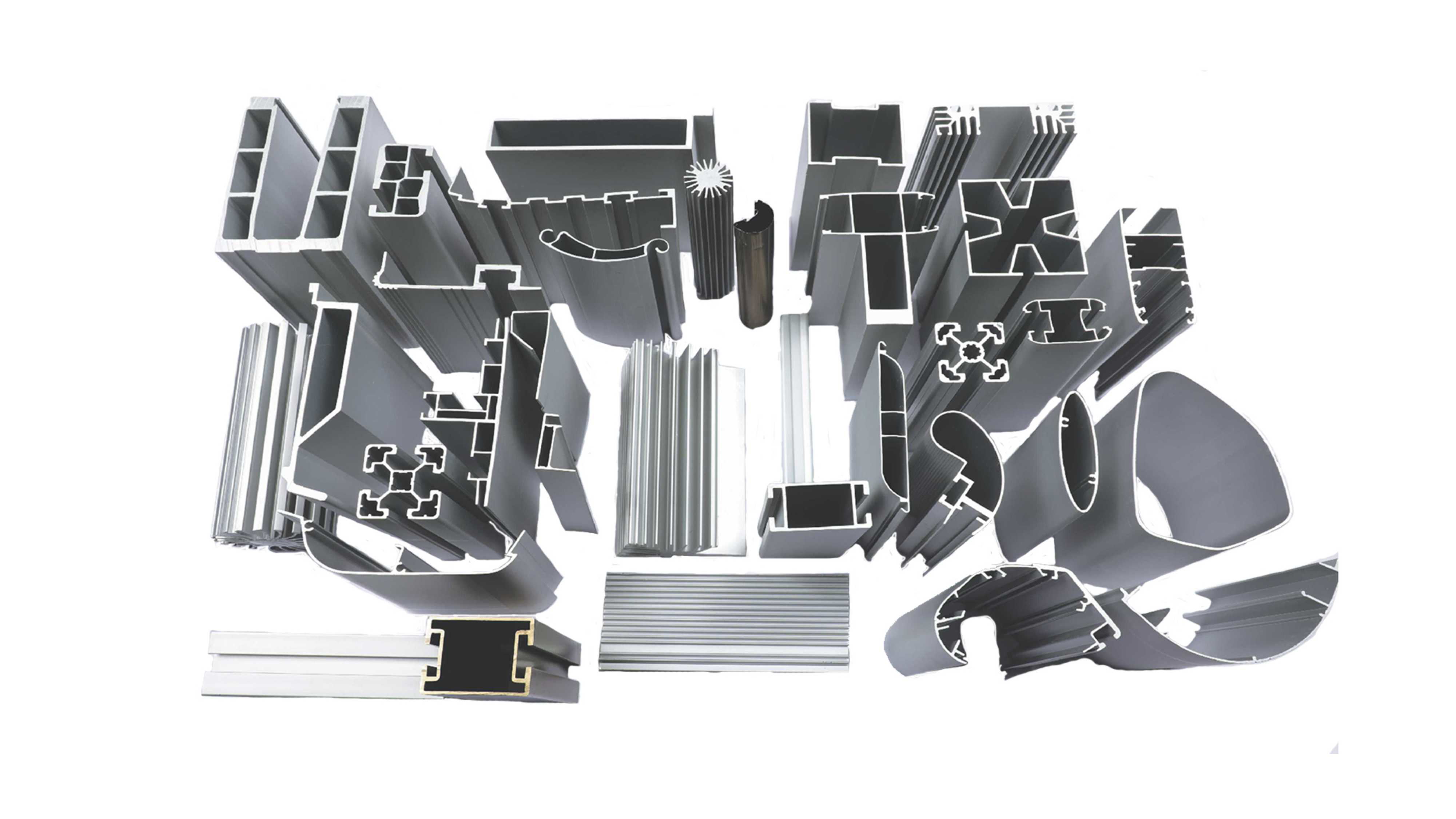

Ka dib markii dusha sare ee profile extrusion aluminium warshadaha waa anodizing, muuqaalku waa mid aad u qurux badan oo u adkaysta wasakhda. Marka lagu dahaadhay saliid, way fududahay in la nadiifiyo. Marka la isku daro badeecada, qeexitaanno kala duwan oo aluminium ah ayaa loo isticmaalaa iyadoo loo eegayo agabyada kala duwan ee xamuulka qaada, iyo qalabyada aluminiumka ah ee isku midka ah ayaa loo isticmaalaa, iyada oo aan alxan lahayn. Aad bay u wanaagsan tahay bay'ada, way fududahay oo way fududahay in la qaado aadna ugu habboon in la guuro.

Marka la barbardhigo qalabka kale ee birta ah, aluminium aluminium ah oo la soo saaray ayaa leh caag xooggan, wax soo saar wanaagsan, wuxuuna leeyahay faa'iidooyin wanaagsan oo wax soo saarka; Aluminium aluminium ah oo warshadaysan ayaa leh qulqulo wanaagsan, waxaa lagu samayn karaa iftiin iftiin leh oo leh walxo badan oo bir ah, maaddaduna waa mid tayo sare leh; extrusion aluminium warshadaha leh modularization iyo hawlo badan, waxay si dhakhso ah u dhisi kartaa jaakad qalab farsamo oo ku habboon.

Waxqabadka daaweynta dusha sare waa mid wanaagsan, muuqaalku waa midab dhalaalaya, rinji looma baahna, iskudhafka barti waa yar yahay, mana jirto wax shil ah oo isku dhac ah iyo isku dhac. Waxay leedahay waxqabadka ugu wanaagsan ee tignoolajiyada baabuurta, ma laha wasakhowga birta, iyo ma laha sun.

Aluminium profiles extrusion profiles ayaa si weyn loo isticmaalaa, sida:

1. Dhismaha aluminium aluminium profiles: aluminium aluminium qaab dhismeedka inta badan waxaa ka mid ah aluminium profiles albaabada aluminium iyo daaqadaha iyo profiles aluminium ee derbiyada daahyada aluminium;

2. Radiator profile aluminium: inta badan waxaa loo isticmaalaa daminta kulaylka ee qalabka elektarooniga ah ee kala duwan, nalalka aluminium LED, iyo alaabta dhijitaalka ah ee kombiyuutarka.

3. profiles extrusion aluminium warshadaha: profiles extrusion guud ahaan warshadaha aluminium waxaa inta badan loo isticmaalaa wax soo saarka warshadaha iyo wax soo saarka, sida mashiinada iyo qalabka iswada, qalfoofka ee xayndaabka, iyo shirkad kasta astaysto caaryada si waafaqsan shuruudaha qalab farsamo iyaga u gaar ah, sida suumanka conveyor line, hoists, qaybiyaha, qalabka tijaabada, shelf, iwm, mishiinka qolka nadiifka ah, iwm.

4. Aluminium profiles extrusion profiles ee qaybaha auto: Inta badan loo isticmaalo qaybaha auto iyo xirayaasha.

5. Qalabka aluminium aluminium: inta badan waxaa loo isticmaalaa muraayadaha qurxinta alaabta guriga, taageerada miiska iyo kursiga, iwm.

6. Qorraxda sawir-qaadista: oo ay ku jiraan aluminium fareemka qoraxda, bracket photovoltaic bracket, xirayaasha tile photovoltaic, iwm.

7. Muuqaalka aluminium ee la sii daayay ee qaab dhismeedka gaadiidka tareenka: inta badan waxaa loo isticmaalaa soo saarida jirka gaariga tareenka.

8. Qalabka aluminium ee la rakibay: oo laga sameeyay muraayadaha sawirada aluminiumka si loogu dhejiyo bandhigyo kala duwan iyo sawirro qurxinta.

9. Aluminium profiles ee qalabka caafimaadka: Inta badan loo isticmaalo bareelo, qalabka caafimaadka, sariirta caafimaadka, iwm.

Aluminium aluminium aluminium ah oo warshadeed ayaa ah walxo aluminium ah oo leh aluminium extrusion oo ah qaybta ugu muhiimsan. Usha aluminiumku waa la dhalaaley oo la soo saaraa si loo helo aluminium oo leh qaabab kala duwan oo isku dhafan, laakiin saamiga daawaha lagu daray waa ka duwan yahay. Mashiinnada wax soo saarka ee waxqabadka aluminium aluminium warshadaha iyo meelaha codsiga sidoo kale way kala duwan yihiin. Halbeegga dhaqangelintu waa waafaqsan GB/T5237.1-2004.

Goobaha codsiga ee profiles aluminium warshadaha: Guud ahaan, profiles aluminium warshadaha tixraacayaa dhammaan profiles aluminium warshadaha marka laga reebo albaabbada aluminium dhismaha iyo daaqadaha, darbiyada aluminium, qurxinta gudaha iyo dibadda iyo extrusion aluminium warshadaha ee dhismayaasha dhismaha.

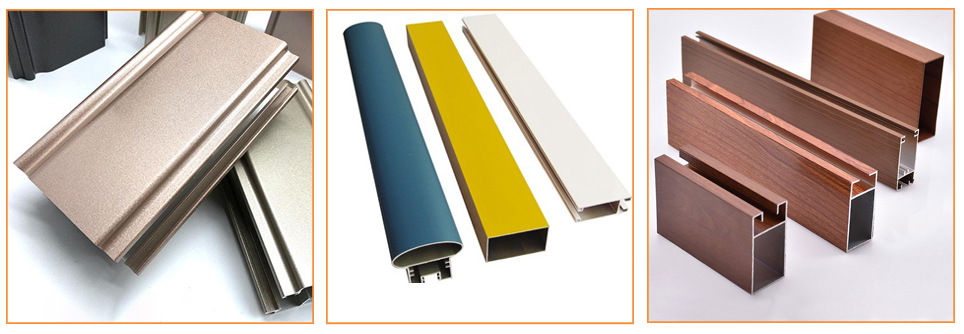

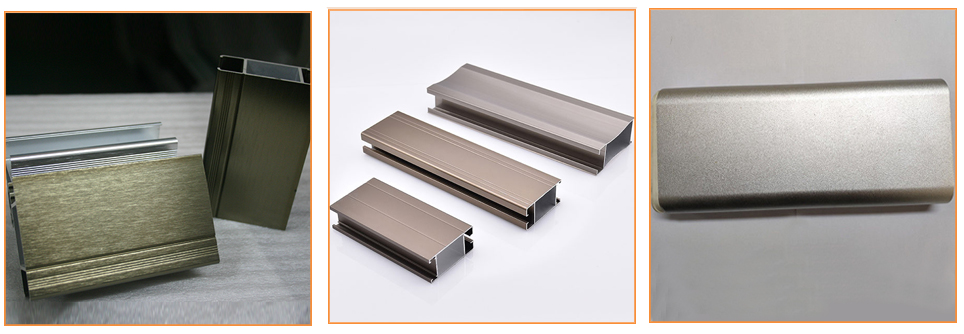

Daaweynta Dusha sare ee loogu talagalayAluminium Profile

Aluminiumku wuxuu leeyahay astaamo kala duwan sida inuu yahay mid xoog badan, oo si fudud loo farsameeyo. Aluminiumku waa bir loo isticmaalo meelo badan, waxqabadkeedana waxaa lagu sii wanaajin karaa daaweynta dusha sare.

Daawaynta dusha sare waxay ka kooban tahay dahaar ama hannaan kaas oo daahan lagu dhejiyo ama lagu daro walxaha. Waxaa jira daawayn dusha kala duwan oo loo heli karo aluminium, mid kastaa wuxuu leeyahay ujeeddooyin u gaar ah iyo isticmaal wax ku ool ah, sida inuu noqdo mid qurux badan, dhejis fiican, adkaysi u leh, iyo wixii la mid ah.

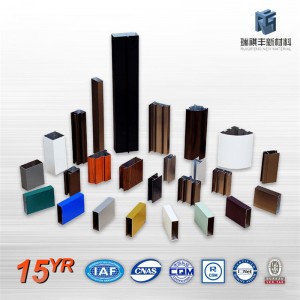

Dahaarka PVDF Dahaarka budada ah ee Hadhuudhka alwaax

Dabaysha Electrophoresis

Ciid-qarxinta Anodizing Anodizing

Haddii aad jeclaan lahayd inaad wax badan ka ogaato daaweynta dusha sare, fadlan ha ka waaban inaad nala soo xidhiidho, bywac +86 13556890771(Mob/Whatsapp/We Chat), ama codso qiyaasvia Email (info@aluminum-artist.com).

Xirmadan isticmaalka guud ee profiles aluminium

1. Baakadaha caadiga ah ee Ruiqifeng:

Ku dheji filimka ilaalinta PE dusha sare. Kadibna profile-yada aluminiumka waxaa lagu duuduubi doonaa xirmo by filimka yaraaday. Mararka qaarkood, macaamiishu waxay waydiisanayaan in ay ku daraan xumbo luul ah oo ku daboolaya astaanta aluminiumka. Filimka yar yar wuxuu yeelan karaa astaantaada.

2. Baakad warqad:

Ku dheji filimka ilaalinta PE dusha sare. Markaas tirada aluminium profiles waxaa lagu duuduubi doonaa xidhmo by warqad. Waxaad ku dari kartaa sumaddaada warqadda. Waxaa jira laba ikhtiyaar oo warqad ah. Duubista warqadda Kraft iyo warqad toosan oo Kraft ah. Habka loo isticmaalo laba nooc oo waraaqo ah ayaa kala duwan. Fiiri sawirka hoose waad ogaan doontaa.

Roll Kraft Paper Toosan Kraft Paper

3. Baakadaha caadiga ah + sanduuqa kartoonada

Baakadaha aluminiumku waxa lagu buuxin doonaa baakad caadiga ah. Ka dibna ku xidh kartoonka. Ugu dambeyntii, ku dar looxa alwaax agagaarka kartoonka. Ama ha ku shubto kartoonku saqafka alwaaxda.  Iyada oo loox alwaax ah oo leh sagxadaha alwaaxa ah

Iyada oo loox alwaax ah oo leh sagxadaha alwaaxa ah

4. Baakadaha caadiga ah + looxa alwaaxa

Marka hore, waxaa lagu xiri doonaa xirmo caadi ah. Ka dibna ku dar looxa alwaaxa ah oo ku wareegsan sida guntimaha. Sidan oo kale, macmiilku wuxuu isticmaali karaa fargeeto si uu u dejiyo muuqaalada aluminiumka. Taasi waxay ka caawin kartaa inay badbaadiyaan kharashka. Si kastaba ha ahaatee, waxay bedeli doonaan xirmooyinka caadiga ah si loo yareeyo kharashka. Tusaale ahaan, kaliya waxay u baahan yihiin inay ku dhegaan filimka ilaalinta PE. Jooji filimka yaraynta

Waa kuwan dhowr qodob oo xusid mudan:

a.Xariijimo kasta oo alwaax ah waa isku cabbir iyo dherer isku xidhmo isku mid ah.

b.Masaafada u dhaxaysa xariijimaha alwaaxdu waa inay siman yihiin.

c.Xarigga alwaaxdu waa in lagu dhejiyaa fiilada alwaax marka la soo shubayo. Si toos ah looguma cadaadin karo astaanta aluminiumka. Tani waxay burburin doontaa oo xoqin doontaa astaanta aluminiumka.

d.Baakadaha iyo rarida ka hor, waaxda baakadku waa inay xisaabisaa CBM iyo miisaanka marka hore. Haddii kale waxay lumin doontaa boos badan.

Hoos waxaa ku yaal sawirka xirmada saxda ah.

5. Baakadaha caadiga ah + sanduuqa alwaaxa

Marka hore, waxaa lagu buuxin doonaa xirmo caadi ah. Ka dibna ku xidh sanduuqa alwaax. Waxa kale oo jiri doona loox alwaax ah oo ku wareegsan sanduuqa alwaax ee forklift. Qiimaha baakaddani way ka sarraysaa kan kale. Fadlan ogow in ay tahay in ay jirto xumbo gudaha sanduuqa alwaax si looga hortago shilka.

Waxa kor ku xusan waa baakadaha caadiga ah. Dabcan, waxaa jira habab badan oo xirxiro oo kala duwan. Waan ku faraxsannahay maqalka baahidaada. Hadda nala soo xidhiidh.

Soo dejinta & Rarista

Degdega Express

Haddi aanad hubin xidhiddee ku haboon adiga? fadlan ha ka waaban inaad nala soo xidhiidho, bywac +86 13556890771(Mob/Whatsapp/We Chat), ama codso qiyaasvia Email (info@aluminum-artist.com).

Socodka Socdaal ee Warshada Ruiqifeng ee Alaabooyinka Aluminiumka ah

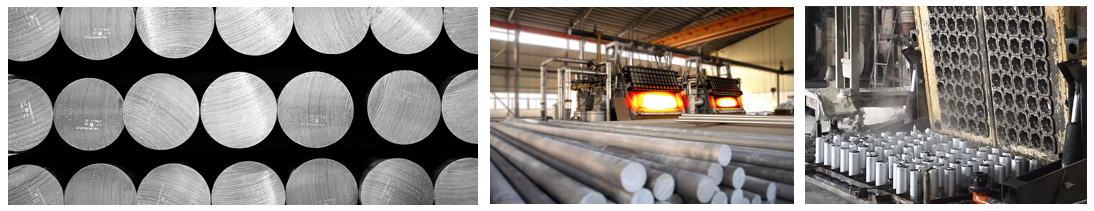

1.Melting&Cating Workshop

Aqoon-is-weydaarsigayada dhalaalidda & jilitaanka, kaas oo xaqiijin kara qashinka dib-u-warshadaynta iyo dib-u-isticmaalka, xakamaynta kharashaadka wax-soo-saarka, oo horumarin kara waxtarka wax-soo-saarka.

2.Xarunta Naqshadeynta Mould

Injineeradayada naqshadeynta ayaa diyaar u ah inay horumariyaan nashqada ugu waxtarka badan uguna wanaagsan alaabtaada, iyagoo isticmaalaya dhitooyinkeena gaarka ah.

3.Xarunta Extruding

Qalabkayaga extrusionka waxaa ka mid ah: 600, 800T, 1000T, 1350T, 1500T, 2600T, 5000T model extrusion of tonnages kala duwan, qalabaysan American-made Granco Clark (Granco Clark) cagaf,kaas oo soo saari kara goobada ugu weyn ee la guday. Noocyada kala duwan ee saxda ah ee saxda ah ilaa 510mm.

5000Ton Extruder Extruder Workshop Extruding Profile

5000Ton Extruder Extruder Workshop Extruding Profile

4.Furnada gabowga

Ujeedada ugu weyn ee foornada gabowga waa in laga saaro diiqada daawaynta gabowga ee aluminium aluminium iyo qaybaha shaabadaynta birta ah. Waxa kale oo loo isticmaali karaa qalajinta alaabta caadiga ah.

5. Aqoon-is-weydaarsiga Dahaarka Budada

Ruiqifeng waxa uu haystay laba xariiq oo daahan budo toosan iyo laba xariiq oo daahan budo ah oo toosan kuwaas oo isticmaalay Japanese Ransburg fluorocarbon PVDF qalabka buufinta iyo Swiss(Gema) qalabka buufinta budada ah.

Xariiqda daboolka budada ah ee tooska ah

Xariiqda daboolka budada ah ee tooska ah

Khadka dahaarka budada toosan-1 Xariiq dahaarka budada toosan-2

Khadka dahaarka budada toosan-1 Xariiq dahaarka budada toosan-2

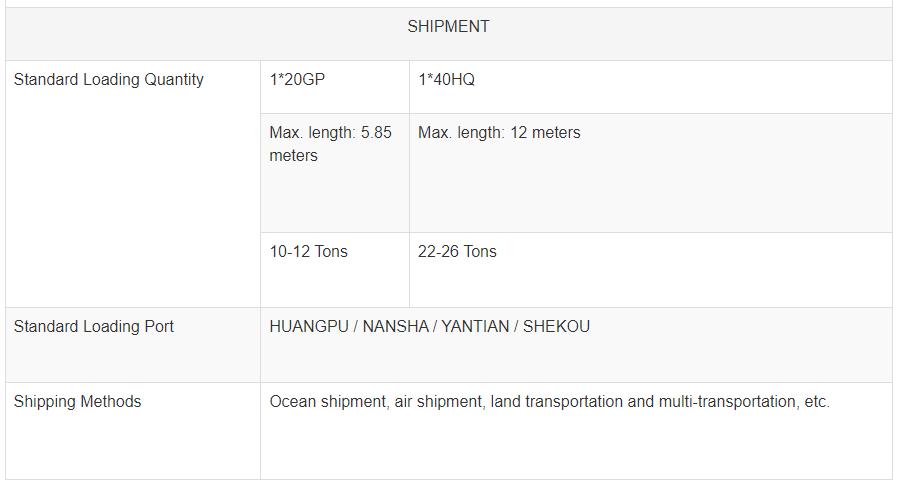

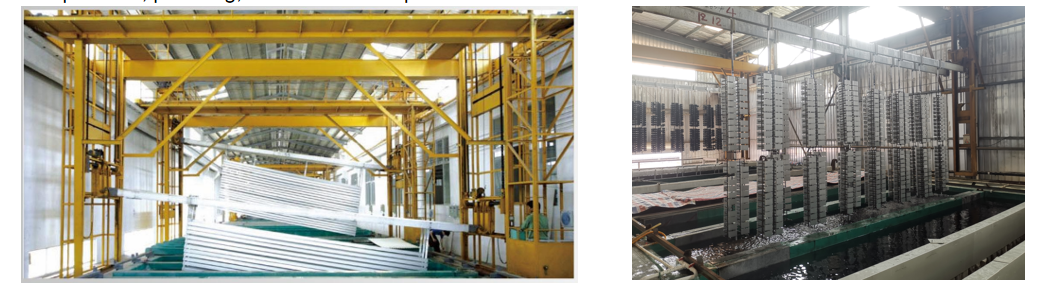

6.Anodizing Workshop

Waxay haysataa oksijiin horumarsan & khadadka wax soo saarka electrophoresis, waxayna soo saari kartaa ogsijiinta, electrophoresis, polishing, iyo alaabooyin kale oo taxane ah.

Anodizing for profiles dhiso Anodizing for heatsink

Anodizing for profiles dhiso Anodizing for heatsink

Anodizing for Profile Aluminium warshadaha-1 Anodizing for Profile Aluminium warshadaha-2

7.Saw Cut Center

Qalabka wax lagu jeexjeexo waa qalab si toos ah oo toos ah oo sax ah oo sax ah. Dhererka miinshaarka waxaa lagu hagaajin karaa si xor ah, xawaaraha quudinta waa mid degdeg ah, jeexdintu waa mid deggan, saxnadu waa sarreeyaa. Waxay buuxin kartaa shuruudaha miinshaarka macaamiisha ee dhererka iyo cabbirrada kala duwan.

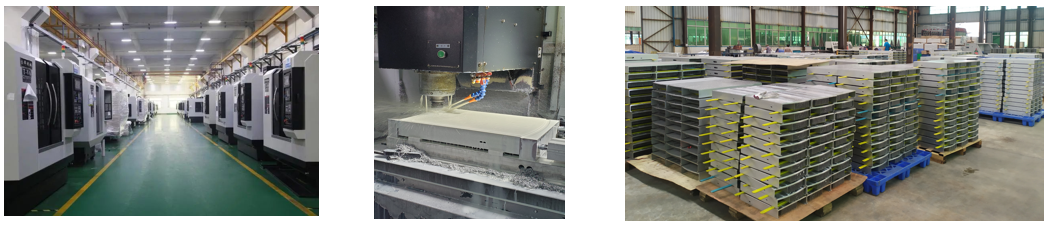

8.CNC Dep Processing

Waxaa jira 18 qaybood oo ah qalabka xarunta mashiinada ee CNC, kuwaas oo ka shaqayn kara qaybo ka mid ah 1000 * 550 * 500mm (dhererka * ballac * dhererka). Saxnaanta mashiinka qalabku wuxuu gaari karaa gudaha 0.02mm, qalabyaduna waxay isticmaalaan qalabka pneumatic si ay si dhakhso ah u beddelaan alaabta una hagaajiyaan wakhtiga dhabta ah ee waxtarka leh ee qalabka.

Qalabka CNC Machining CNC Dhamaystirka alaabta

9. Xakamaynta tayada -Tijaabada Jirka

Ma hayno oo kaliya kormeerka gacanta ee shaqaalaha QC, laakiin sidoo kale Qalabka cabbiraadda Isku-dubbaridka Sawirka Tooska ah si loo ogaado cabbirka aagga is-goysyada ee heatsinks, iyo qalabka cabbiraadda isku-dubarid 3D ee kormeerka saddex-geesoodka ah ee cabbirka wareegga oo dhan ee alaabta.

Tijaabada gacanta ee Tooska ah ee Isku-dubaridka Sawirka Mashiinka Cabbirka ee 3D

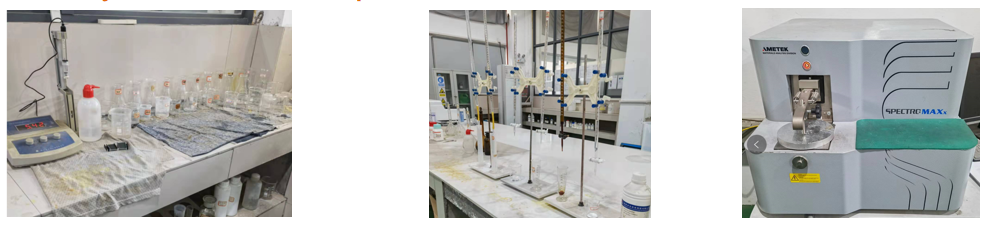

10.Kontoroolka tayada-Tijaabada Halabuurka Kiimikada

Tijaabada isku dhafka kiimikaad iyo tijaabinta-1 Halabuurka kiimikaad iyo tijaabinta-2 Falanqeeyaha Spectrum

11.Quality control-Tijaabada iyo qalabka tijaabada

Tijaabada xamaasadda Cabbirka sawir qaadaha Tijaabada buufinta milixda Heerkulka joogtada ah iyo huurka

12.Baakad

13. Rarista & Rarista

Sahayda Saadka-Silsiladda Shabakadda gaadiidka ku habboon ee badda, dhulka iyo hawada

Sida aan wada ognahay, dhaqaaluhu aad uma fiicnaan doono sanadkan sababtoo ah saameeyay isku dhacyada juqraafiyeed iyo kor u kaca heerka dulsaarka si loo xakameeyo sicir bararka.

Shirkado badan ayaa la kulmi doona cadaadis kharash. Markaa waxaanu ka fikiraynay nooca faa'iidooyinka aan u keeni karno macaamiisha mustaqbalka?

Haddii aad daawataymuuqaalka shirkaddaBoggayaga Guriga ama Soodejinta, waxaad ogaan doontaa in faa'iidooyinkayadu yihiin kuwan soo socda:

Ⅰ Waxaan joognaa goobta kheyraadka ee bauxite, Guangxi bauxite khayraadka leh kaydka ugu weyn iyo tayada ugu fiican ee dalkeena;

Ⅱ Ruiqifeng waxay wada shaqayn dhow la leedahay laanta caanka ah ee Guangxi ee CALCO:

1. Waxaan leenahay qiimo tartan. 2. Qalabka dareeraha ah ee aluminium tayo sare leh, tayada alaabta waa la dammaanad qaaday.

Ⅲ Naqshadeyntayada hal-joojinta iyo xalalka wax-soo-saarka waxay xaqiijin kartaa xasilloonida badeecada waxayna badbaadin kartaa dhammaan waqtiga bixinta.

Haddaadan hubin shayga kugu habboon? fadlan ha sameynka labalabayn inaad nala soo xidhiidho, bywac +86 13556890771Mob/WhatsApp/Waan wada sheekaysannaa), ama codso qiyaas iyada oo loo marayoEmail (info@aluminum-artist.com).